Expertise

IMS International (IMSINT) naval architecture and allied engineering capabilities are used in new ship designs as well as vessel conversions and alterations, with a focus on custom designs to fit customers’ specific requirements. Being a naval architecture expert in Singapore provides engineering and customized engineering scopes of work based on a thorough understanding and analysis of their stakeholders’ needs. To optimize the most efficient vessel, they use the most up-to-date marine technologies and applications. This is true whether the project entails a full set of shipyard production designs for a new structure or a minor vessel modification.

Their supervisors and inspectors have provided services at a number of shipyards around Asia to guarantee compliance of contract with no flaws. They have been trusted to deliver on time and with transparency on every project that has been awarded to them, and they have done so effectively.

Marine Design

Baseline Conceptual Design & Feasibility Studies

IMSINT’s naval architecture team based in Perth develops outline design and outline specifications for a variety of marine applications.

Design requirements are identified, analyzed taking into account physical, economic, technological and operational aspects.

Based on these a suitable concept design is prepared along with outline specifications.

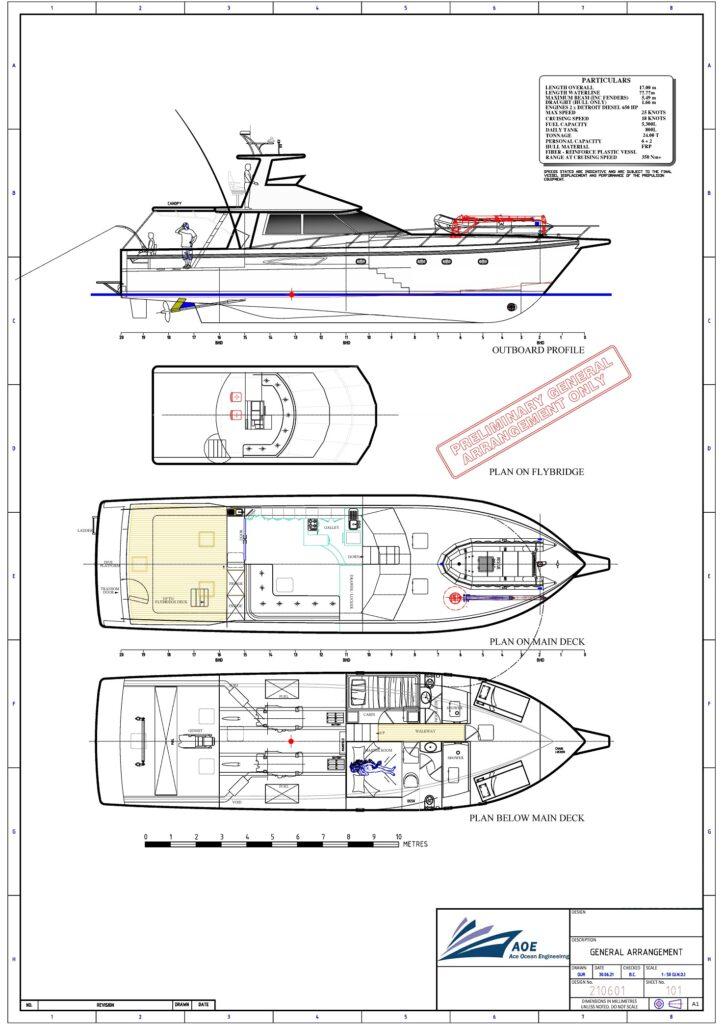

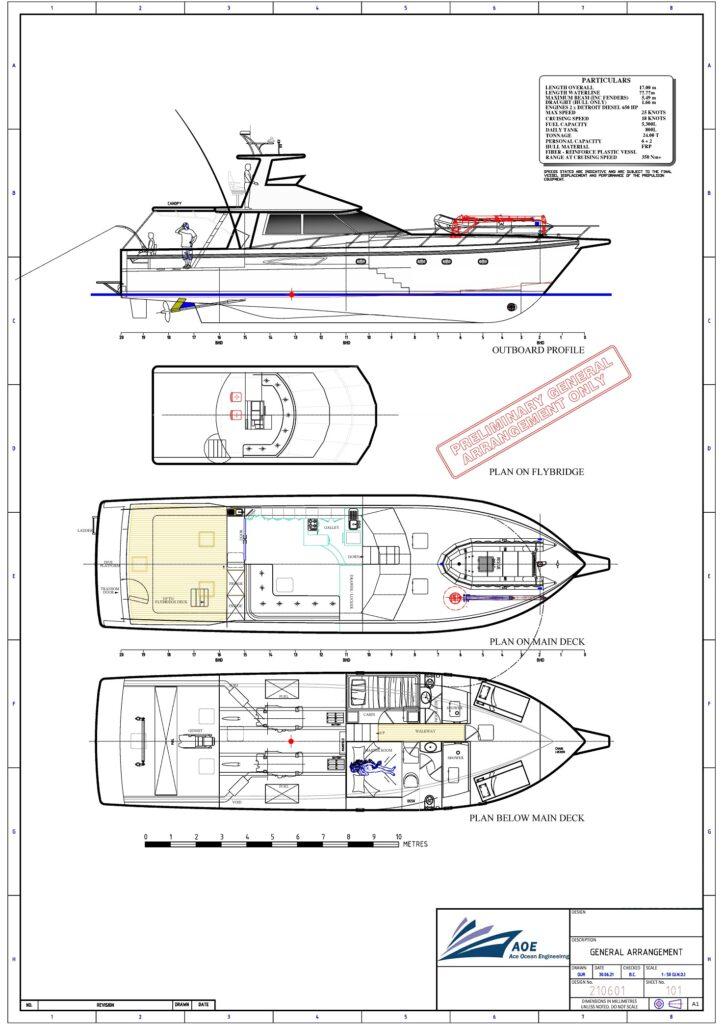

General Arrangement (GA) / Specifications

IMSINT has developed in-depth capabilities to carry out Basic Design. They utilize their experience gained from the building processes at the various shipyards that they work with and the feedback obtained from vessel operators and equipment manufacturers, to enhance design capability and develop safe and efficient designs for our customers. This has enhanced their design capability in developing safe and efficient vessels for their customers.

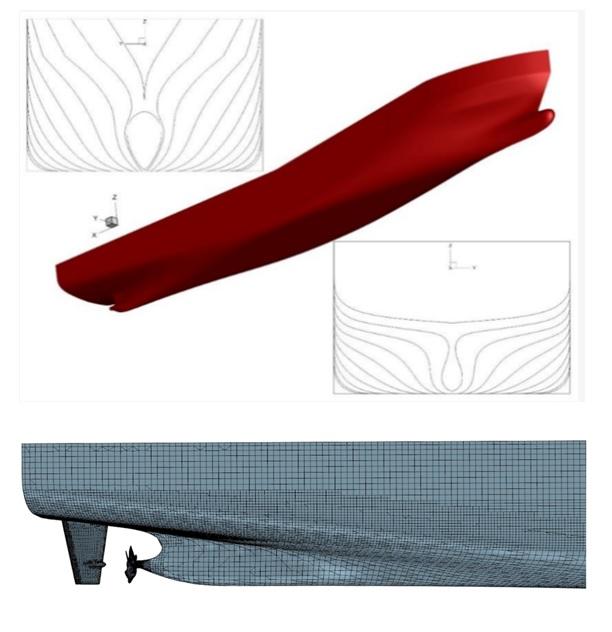

Optimised Hull Form Design

Shape optimization is a growing field of interest in marine design. With computational tool sets and process framework informed decisions regarding the influence of the planned hull shape on its hydrodynamic characteristics can be made.

IMSINT, being a strong implementer of best technology offers Hull Form Optimization for a wide variety of Marine Projects

Hull Design & Naval Architecture

Their naval architects have expertise and required acumen in the design, construction and surveying of many vessels and have built vast in house data.

They use industry recommended software tools and in house developed excel sheets for completion of projects .

The following naval architecture services like

- General arrangement drawing, Specification and equipment list preparation

- Equipment and machinery selection of the vessel

- Stability analysis of marine structures including intact stability, damage stability, probabilistic damage stability

- Midship section design based on classification regulations and in house FEM calculation

- Preparation of Statutory drawings and documents for the vessel including navigation arrangement, escape routes plan, fire plan, life saving plan, tonnage calculation

- Deadweight surveys, inclining test and sea trial consultancy services and on board stability calculation sheets

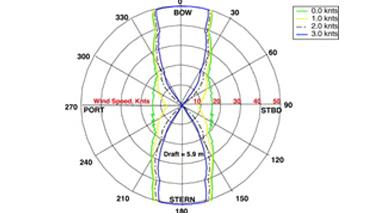

- Ship and offshore structure’s motion calculation by regulatory guidelines or using industry standard software tools

- Determining resistance of ship for power estimation and further engine power and propeller selection

- Calculation of RAO of the vessels to ascertain operability and various other responses

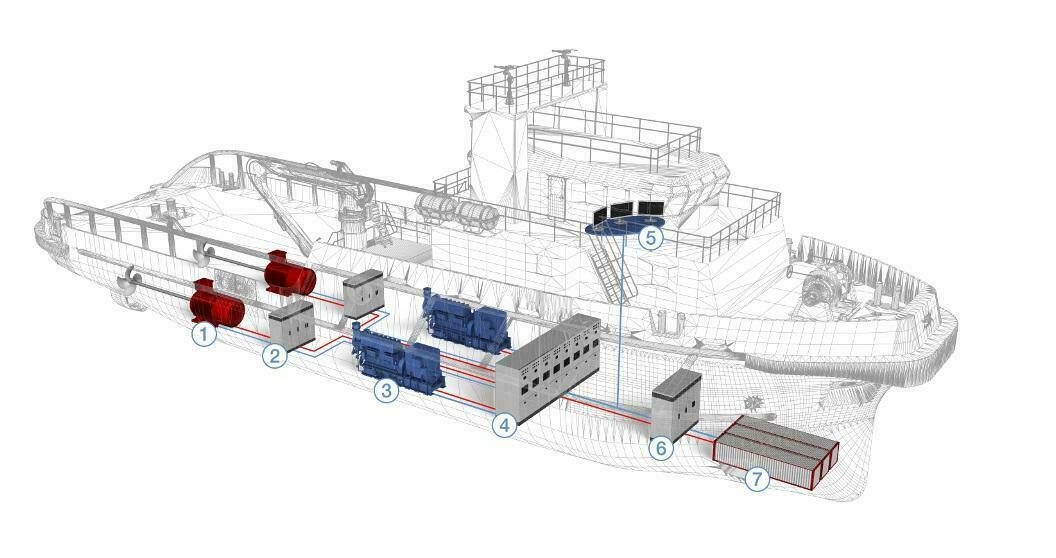

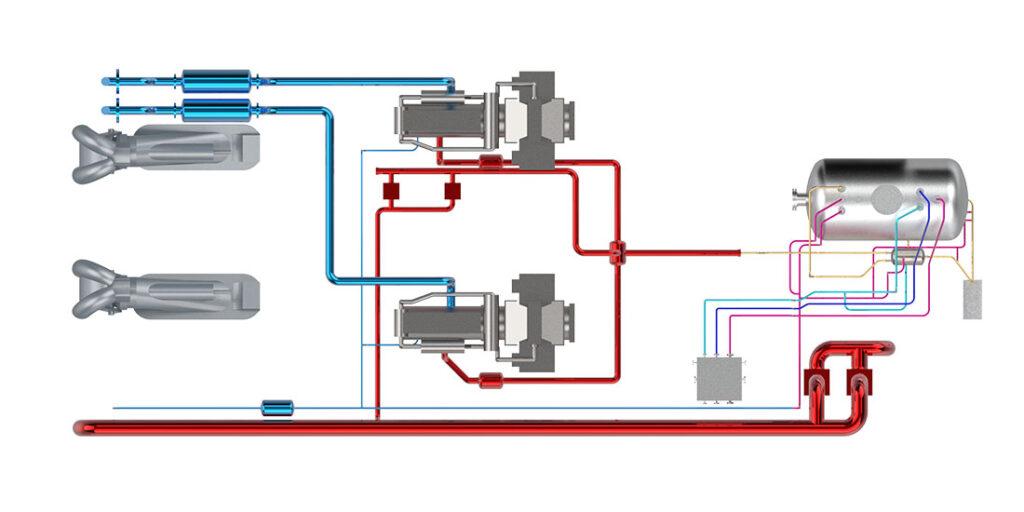

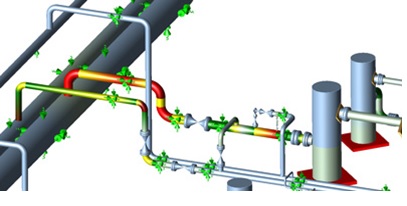

Mechanical / Piping / Machinery

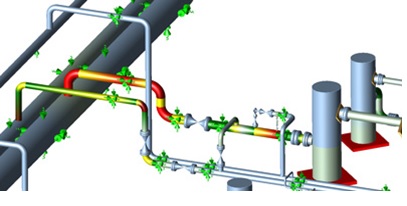

They carry out a host of activities in this area like Layouts, Machinery Sizing and Specifications, creating P&ID’s, 3D Modelling, HVAC Ventilation Systems, Spool Drawings etc.

The following basic design and conversion solutions for these ship and offshore systems are provided

- Water Ballast System

- Bilge System

- Fuel Oil System

- Lube Oil System

- Fuel Oil coolant system

- Lube Oil Coolant System

- Fire System

- Ventilation and Exhaust arrangement

- HVAC system

- Hydraulic System

- Pneumatic System

- Propulsion Arrangement

- Steering gear room arrangement

- Sprinkler System

- Black & Gray water System

- Air Vent System

Electrical Instrumentation & Automation

IMSINT also specializes in developing Electrical, Instrumentation and Automation Designs. Generator, Electrical Routings, System Drawings and other specialty is provided

Outfitting

IMSINT develops outline design and outline specifications for a variety of marine applications.

Design requirements are identified, analyzed taking into account physical, economic, technological and operational aspects. Based on these a suitable concept design is prepared along with outline specifications.

LNG, LPG FGSS & Bunkering System Design

IMSINT has competent team in developing System Designs for LNG, LPG, FGSS and Bunkering Systems.

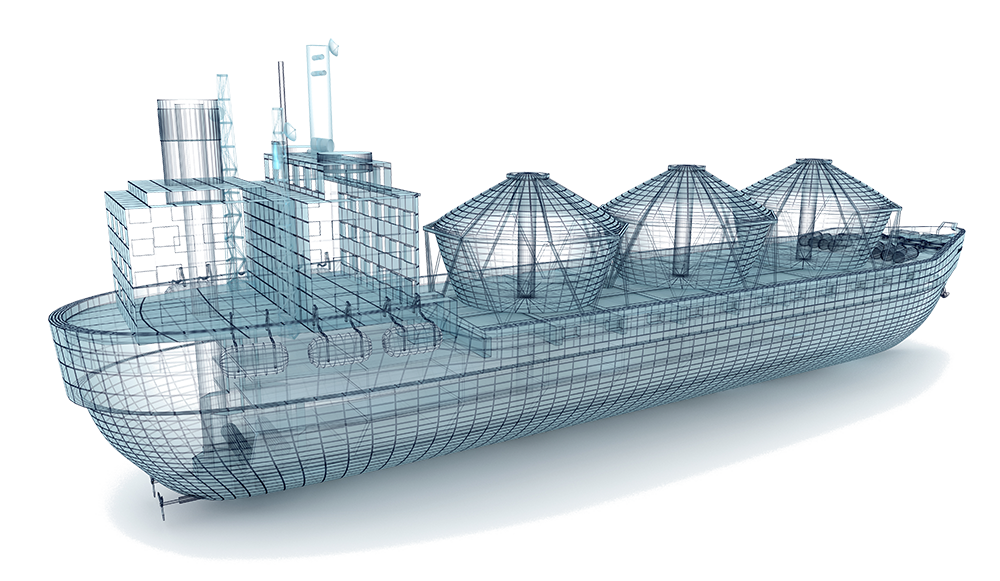

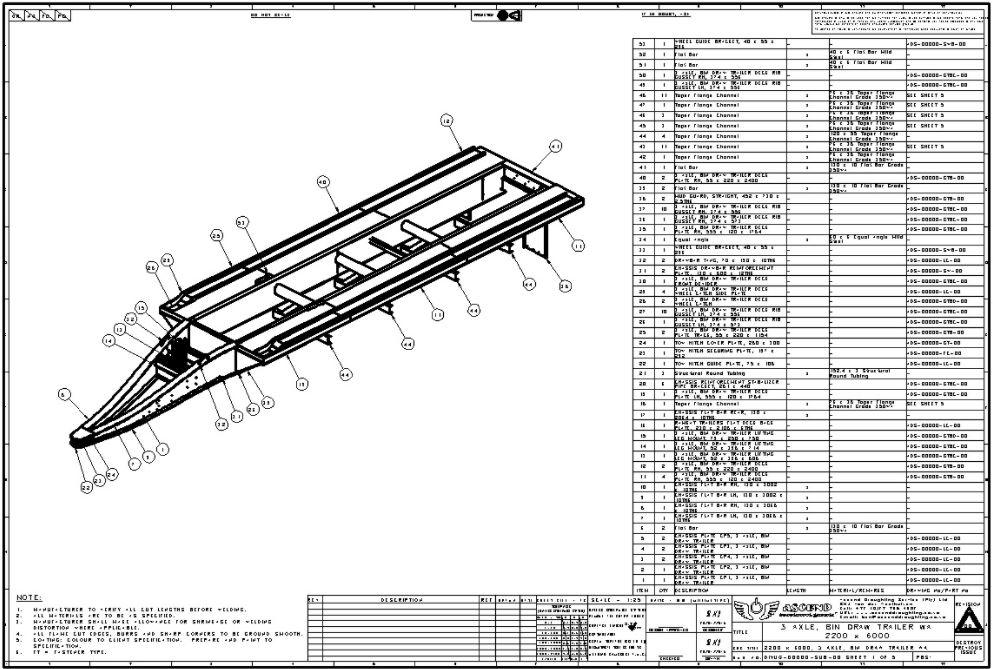

Production Drawings / Production Information

Production Drawings are a crucial component of a Ships Project Cycle, accuracy and detail being a paramount here.

IMSINT’s experience and competent team ensures aproduction drawing of the highest standards.

Some of theme are listed below-

1) Product hierarchy – Defines assembly sequence and build strategy

2) Hull – Creates complex surface models and Pin jig drawings

3) Structure – Provides features such as plate parts, stiffeners, corrugated plates.

4) Weld management – Creates welding schedules

5) Nest and Profile – Creates nesting files

6) NC PYROS – Configures direct interface to CNC machine for cutting

7) Equipment – Models all equipment and inserts into the ship model

8) Pipe – Complete 3D production model for pipe systems

9) HVAC – Easily creates complex HVAC runs relative to structure

10) Penetrations – Allows the creation of intelligent penetration through structural members

11) Reports – Allows for definition and maintenance of complex production detail reports.

Naval Engineering

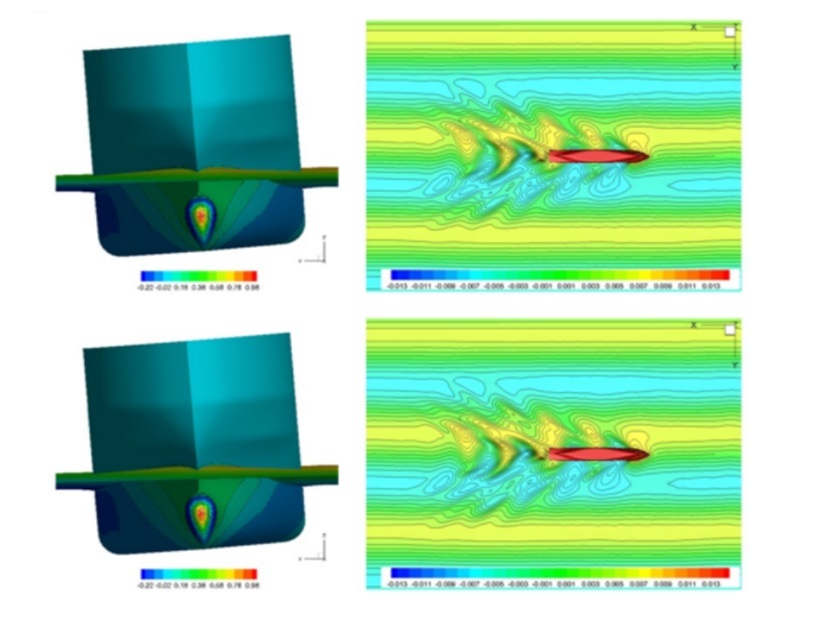

Model Tests & CFD

Aerodynamic CFD simulation of superstructure being well established, the superstructure of ships and offshore structures includes complex arrangements, imposing high vortical flows, which becomes very significant for resistance prediction.

Correct estimation of three dimensional flow around these structures, proves CFD a ultimate tool for ships and offshore structure already in construction phase.

IMSINT with years of experience, has carried out CFD on complex systems and posses the capabilities to take on challenging projects in the future.

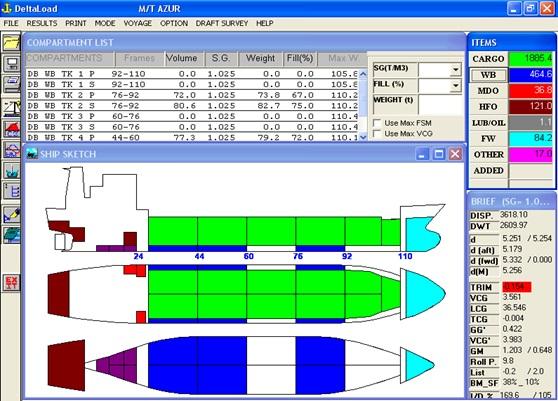

Stability & Inclining Experiments

Intact stability is the basic and utmost check for ship’s sea worthiness and very important when ship is not damaged.We have done intact stability using various codes and regulation. This criteria mainly includes area ratio checks,minimum area requirement up to down flooding angle or angle of vanishing stability,Angle for max GZ position and minimum GM etc.

The compliance is checked mainly against unprotected downflooding points where idea is mainly to check contingency in case of sudden heel due to gust wind or wave. Defining Various loading conditions like lifting, anchor handling,towing, weather etc are very important for worst case Intact stability check.

Different classification societies have different set of intact stability rules however most of these rules have been extracted from IMO code. Many special conditions Intact stability checks are performed with different codes like for Towing, lifting, fire fighting, anchor chain handling.

Sufficient GM is very important for Intact stability check and always regarded as one of the most significant indicator for sufficient stability. We have years of experience in working with the ABS, Lloyds, DNV, BV, USCG and IMCI, and can quickly prepare a stability analysis that is fully compliant and rapidly reviewed and approved by these organizations. designs for our customers. This has enhanced our design capability in developing safe and efficient vessels for our customers.

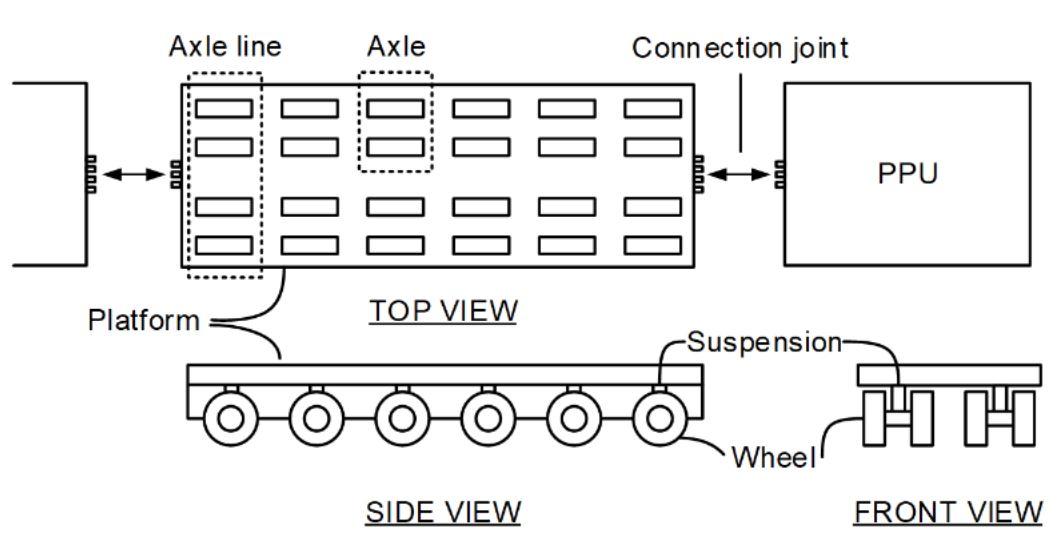

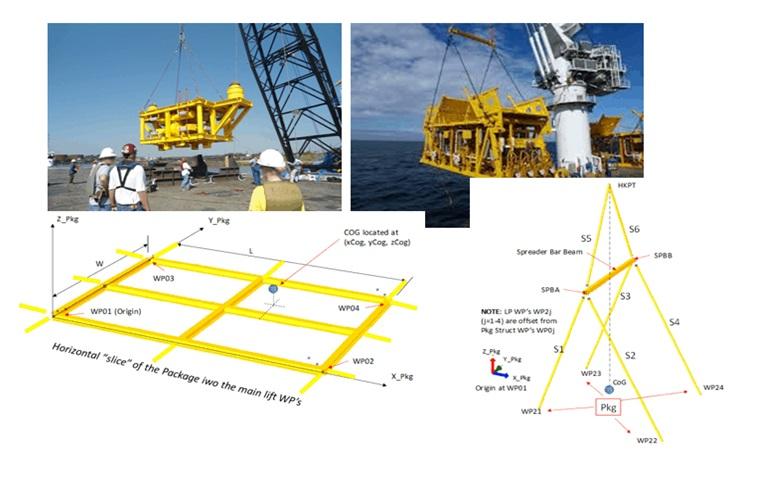

Load Out

Load Out is a very crucial process in ship industry and involves a lot of complications and intricacies to be dealt with.

IMSINT provides load-out analysis and calculation for unloading structures etc.

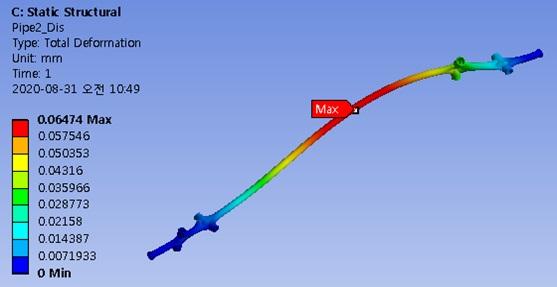

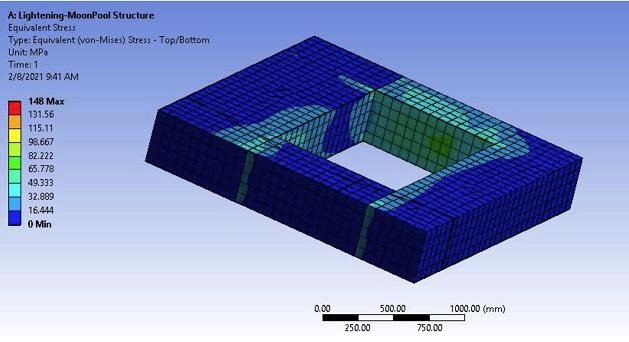

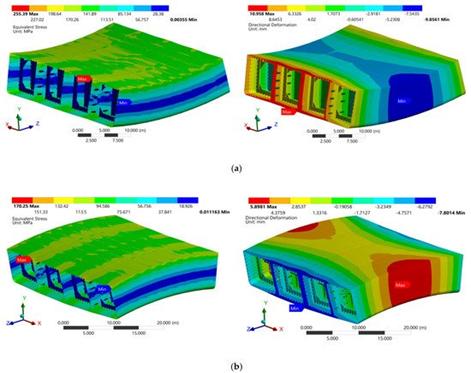

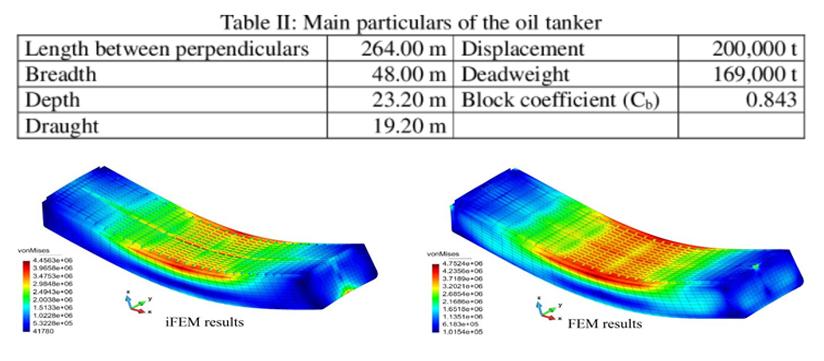

Structural Analysis (FEM)

IMSINT provides customized structural engineering consultancy services including ship hull design and offshore engineering starting from feed to economical solution and completion with engineering supervision in the fabrication, and regulatory certification stage.

Their experienced naval architects and structure engineers having wide skills in the fields of hull design, analysis, production support and deep knowledge of the shipbuilding, marine industry and offshore industry (DNV, ABS, RINA, ASME, API) provide best solutions.

They emphasize on continuous feedback and supervision with shipyards and manufacturers, where continuous feedback, monitoring and testing reduces production issues and increases significantly reliability within the entire lifetime of their design.

Application of modern CAD software (AUTOCAD) allows for efficient passage from conceptual to detailed design phase (fabrication drawings and 3D models for structural analysis) ensuring the necessary flexibility to adapt to changing customer needs.

Software like ANSYS, STAAD, etc. allows for analysis and optimization of structures for yielding, buckling, and fatigue failure modes.

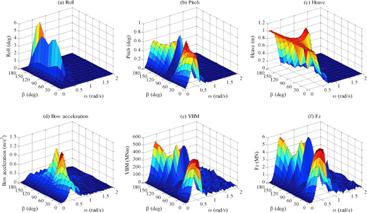

Hydrodynamic Analysis/ Motion Analysis

IMSINT offers multiple area of modern experimental assessment ways to cover many different types of marine and offshore structures model tests. They have been providing excellent service to provide exact prediction of power requirements for the full-scale ship from the model test results. Apart from that, excellent services in the model test procedure preparation and test follow-up to ensure best execution and estimation of results.

Before model test they provide these services:

• Model test procedure and consultancy

• Coordination with Towing tank company

• Model test results estimation via. CFD

• Vessel lines optimization and Propeller design

After model test they provide clients:

• Evaluation of measuring points

• Preliminary prognosis calculation after every model test run

• Vessel basic parameters and lines optimization

• Optimization of ship geometry appendages by CFD calculations

SHIP MOTION ANALYSIS

• Multi structures and sub-structures motion interaction

• Anti heeling tank design by Tank analysis with ship couple motion

• Wave resistance estimation

• Motions, loads RAO calculations

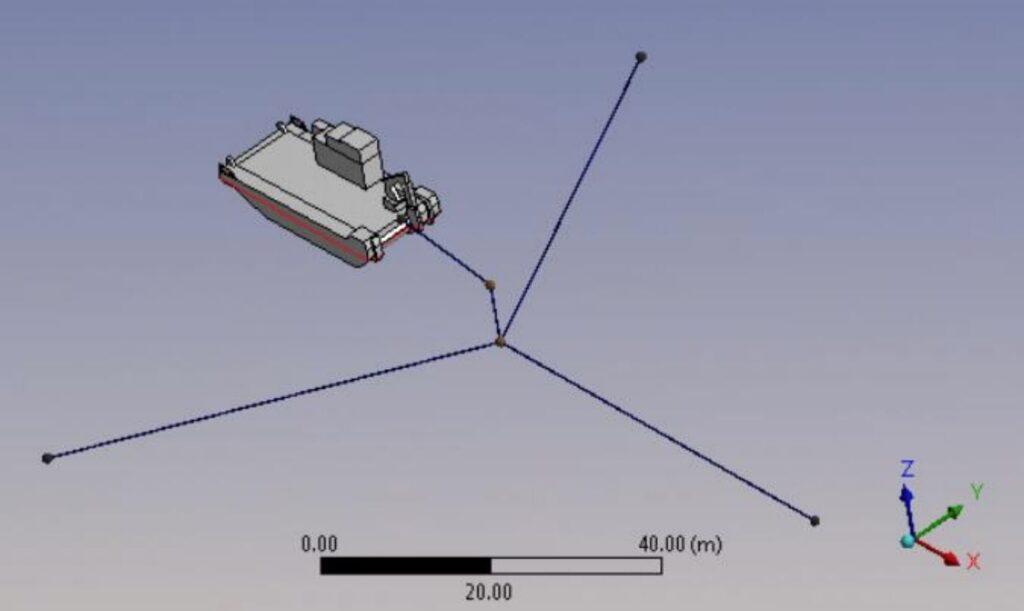

• Complex mooring analysis using multiple items (lines, fenders…)

• Natural periods and critical damping estimation

• Barge and ship’s drift load estimation

• Slamming load estimation

• Deck wetting/ Green water load phenomena

• DP analysis

• Bilge Keel performance prediction

• FPSO motion analysis to ascertain velocities and accelerations at different control points which will be further used in FPSO module support designs.

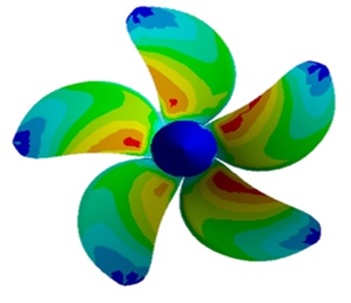

Propeller Design & Powering

The design of marine propellers, involves a series of trial-and-error testing to balance the vessel, engine, shaft, and blades (among other factors) to find the best optimal efficiency for that particular craft. Advances in the past couple of decades with the advent of computers and the ability to perform computer simulations have drastically improved how testing is done.

IMSINT carries out many activities important being the Blade Optimisation, Frequency Seclection, Propeller Diameter Selection, Skew Blade Shape Design, Optimal Pitch Determination.

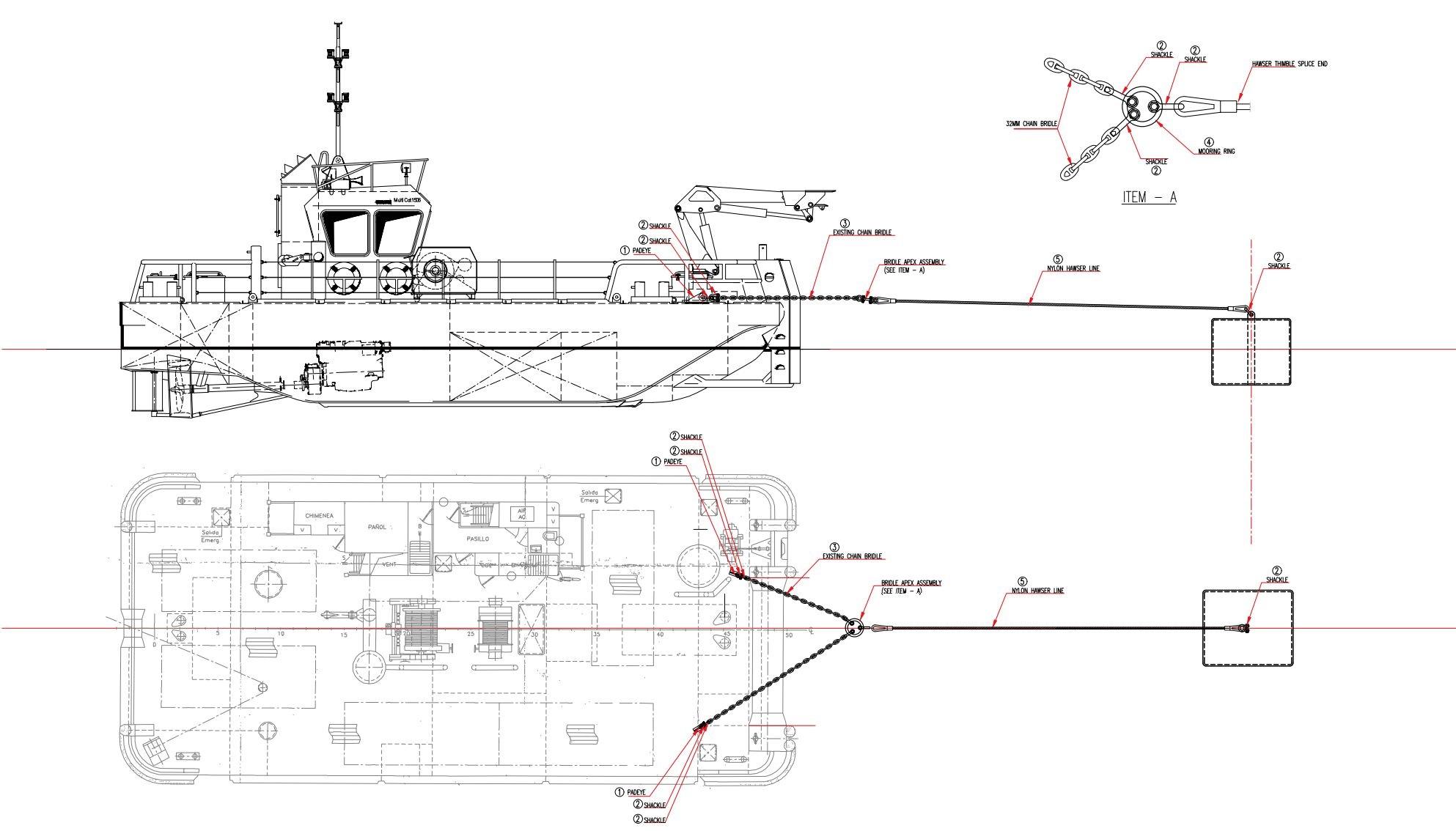

Mooring Analysis

A mooring analysis study is carried out to ensure that a mooring system is suitable for keeping a vessel in place under the specified environmental conditions. A mooring analysis report may be necessary for a variety of reasons, but are not limited to:

- A different vessel is to be moored to an existing mooring system;

- Some mooring components have been replaced or degraded;

- Environmental conditions have changed or been reviewed.

The mooring analysis study will calculate the moored vessel’s maximum loads and offsets in the design environment.

IMSINT can swiftly analyze a mooring system’s suitability for a specific set of operational needs.

Engineers from AOE have done a lot of work.

They are able to analyze frequency and fully coupled, time domain mooring analysis for floating vessels, FPSOs and FSOs

- Spread mooring

- Single point mooring

- Semi-Submersible Platforms

- Tendon Leg Platforms

- Drill ships

- Accommodation vessels

- Mooring during offshore operation

- SPARs

Their engineers are capable of RAO calculation through industry renowned FEM packages which will be further utilized to calculate vessel motion and mooring requirement.

They can provide expertise in the following areas:

- Wire-Chain Catenary Mooring analysis

- Taut Polymer Mooring Analysis

- Pile/Anchor Specification

- Air Gap Calculation

- Coupled Mooring-Riser-Vessel Analysis

- Mooring Fatigue Assessment

- Hydrodynamic Vessel Motion and mooring assessment

Block Turning & Lifting Analysis

Block Turning and Lifting are basic aspects in a ship building story. With higher demand and optimization, ships are being designed to provide maximum benefit or output. With requirement of design efficiency comes complexity especially when it comes to erecting ship components. Hence, a thorough analysis ensures feasibility and safety of a particular block turning and lifting analysis.

Engineering Support

Engineering Support is vital for marine companies to tap their full potential. AOE provides complete support solutions to marine companies in need of engineering support.

FEED

Front End Engineering Design which is the vital phase of any engineering project entails collection of data, assessing the feasibility of the project, finding the best approach and many such activities that ultimately form a foundation for the project as a whole.

FMEA

IMSINT offers a simulation based FMEA which has lot of advantages over the traditional approach.

Pipe Surge Analysis

Pipe surge being a major a major concern in cargo transfer systems of the type used in tanker loading-unloading facilities, brings the need of carrying out Pipe surge anlysis to prevent excessive high pressures during system operations.

Operation Manuals

Operating Manuals which are very crucial when it comes to Shipbuilding, provides the user guidance and awareness on the do’s and dont’s of the the equipment, process etc.

- Cargo Securing Manual

- Procedure and Arrangement Manual

- Emergency Towing Booklet (ETA Manual).

- Operation Manual

- Garbage Plan

- SMPEP Plan

- Tonnage and freeboard calculations

- SOPEP manual

- DP manual

- FMEA Report

- Operating Manual

- Helideck Operation Manual

- DP Operations Manual

- Sea Trial Plan

- Dead Ship Recovery Test

- Rescue Boat Launching Test

- Anchor Drop & Hoist Test

- Thruster Control Validation

- Thruster Sea Acceptance Test

- Speed Log Acceptance Test

Project Management & Supervision

Project Management

With projects, IMSINT caters to ship owners by providing a one-stop destination for its design and site supervision requirements

Project Supervision

IMSINT offer extensive onsite services and provide comprehensive and integrated solutions to the client covering a wide range of services from supervision for new structure, conversions and repairs, sea trials, inclining experiment and life extension surveys.

IMSINT’s Naval architects and Engineers being experienced in new building and repair supervision have in-depth knowledge and awareness of internationally accepted quality standards and regulations of various classification societies.

The host of services Ace provides are follows-

- Prepare a QAP (Quality assurance plan) in line with the shipyard’s practices

- Identify and correct shipbuilding practices leading to quality problems at later stages

- Prepare and implement Shipbuilding standards for hull, outfitting and piping

- Establish and introduce quality control checks at different stages of shipbuilding and repairs

- Arrange training for workers and foreman to improve their skill and bring them in congruence with the quality philosophy of the shipyard.